|

How A Compact Disc Is Manufactured

by Michael Wesolowski

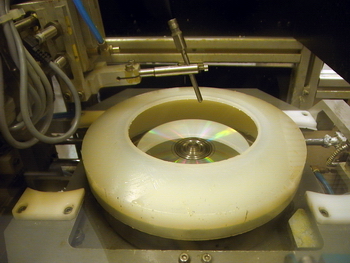

One of the machines used to imprint the information onto the CD.

|

|

Remember Albany Indestructible Cylinders?

(They destructed) Remember Decca

Unbreakable Records? (They broke)

Remember the early advertising for compact discs

as "Perfect Sound Forever"? As always, donít

believe the marketing hype. The compact disc is

indeed a technological wonder, but it is still not the

pinnacle of recorded sound media.

In order to be an educated consumer, one must

understand the manufacturing process of a compact

disc. A CD is a digital delivery system. Anything

that can be digitized can be placed on a CD or CD-

ROM. In the case of an Audio CD,the original

music must be converted to binary code first.

(Computer 1ís & 0s) For every second, the music

is sliced into 44,100 samples per channel.

These samples are 16 bits long. ("1001111000101001"

would be one sample, from one channel) This

binary number, when decoded, represents a certain

positive or negative voltage. String the voltage

changes together, and an analog waveform starts to

appear.

Please keep in mind this is a very basic view of

how CDs work. For the sake of simplicity,

I will not be taking into account the specific ways the

data is encoded. For those wanting the full story,I

highly recommend "Principles of Digital Audio

ó 4th edition" by Ken C. Pohlmann (McGraw-Hill

Video/Audio Professional).

Ultra violet lacquer being spin-coated onto the CD.

|

|

It is this 44.1k, 16-bit sample that many

professional audio engineers feel is inadequate.

In a studio setting, when having the original analog

recording for direct comparison, the current digital

standard falls just short of capturing the full analog

sound. The sound stage collapses a bit with digital.

This is why many companies are introducing

"Super CDs" having 24 bit word lengths and a 96k

sampling rate. (Better Perfect Sound Forever)

Once the music has been encoded into binary digits

and stored either on digital tape, hard drive or

CDR, a glass master is made. A glass master is a

round thick piece of optically pure glass. It is spin-

coated with an even layer of dye that is reactive to

laser light. The glass is put inside an enclosed

turntable and a LBR (Laser Beam Recorder) head is

aimed at the glass. While the glass is rotated, the

LBR pulses on and off, burning tiny pits in the dye

using the binary code from the master. The tiny pits

are formed in a spiral from the inside

of the glass to the outside.

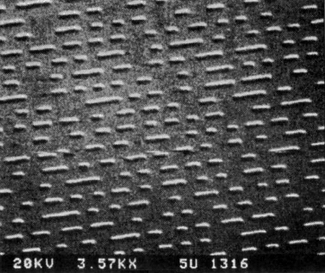

These pits are small, very small. On average, a CD

will contain 15 billion pits. The pits are 1/2 micron

wide (one micron = one-millionth of a meter), 0.1

micron deep, and vary from 0.8 to 3.0 microns in

length. The spiral tracks are spaced 1.6 microns

apart. For perspective, a human hair is 75 microns

in diameter; a fingerprint is 15 microns thick, and

an average piece of dust is 40 microns thick.

A close up view of the pits on a CD.

|

|

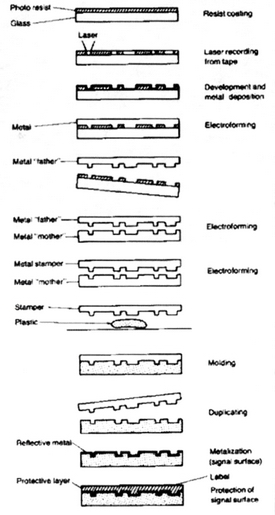

The next step is to grow a metal layer onto the

glass. Sputtering and electroplating are used to

cover the dye with metal, with the metal flowing

right to the glass where the dye has been removed

by the laser. After the metal has been built up to the

desired thickness, the metal layer is pulled away

from the glass and dye. The outer and inner

dimensions of the metal are cut, and the backside is

polished. This is called a Father, and can be used as

a stamper to press CDs. The Father can also have

metal grown on it, and a Mother created. The

process is repeated, and Sons are created. The Sons

can be used as well to press CDs. (The Mothers can

NOT be used for pressing since the pit structure

would be in reverse). The glass master is simply

washed off, polished, coated with dye and used

again for a new project.

With the digital data now encoded in the pits of the

stamper, the stamper is placed into an injection

mold cavity. The cavity, when closed, is the exact

dimensions of a CD. A small hole in the middle of

the cavity is where plastic is injected into the mold

at high pressure. The plastic conforms to the shape

of the mold, one side being smooth, while the other

will have small pits pressed into it from the

stamper. The plastic is allowed to harden, (3

seconds) and the now clear CD rolls down a

pathway to make room for another CD to be

pressed.

At this point, the data is on the CD. It is

permanently stamped into the plastic. The only

reason it cannot be played is the simple lack of a

reflective layer. Inside your CD player, a laser will

shine through the underside of the disc, and bounce

back into the lens as it hits the reflective layer.

(Aluminum in most cases, but can also be 24K

gold). The depth of the pits is bigger than the

wavelength of the laser. This allows the returning

laser beam to be read by the CD player which can

readily identify the edges of the pits and lands to

interpret them as 1ís and 0ís.

The steps in manufacturing from the master to the

final product.

|

|

Obviously the next step would then be to apply a

thin layer of metal to the pit side of the disc. This is

done via a sputtering process. The clear disc is

placed in a vacuum chamber, with an electrical

charge being applied to one end of the

cathode/anode system. Aluminum particles from a

solid circular brick of aluminum try to find their

way to the other side or the charged field. However,

with the clear disc in the middle of the chamber, the

aluminum particles strike the disc instead, coating it

with a very thin reflective layer. As the CD leaves the chamber,

it is now ready to play is any one the CD players around the world.

Now that the discs can be played, we need to make

sure they last "forever". Metal will oxidize when

exposed to air. The metal coating is so thin; it will

disintegrate in a matter of months if left

unprotected. To stop the oxidation, and to protect

the pits, a thin layer of UV (Ultra Violet) cured

lacquer is spin-coated onto the metal surface. The

CD is spun slowly at first while a small amount of

the lacquer is placed near the center. The disc is

then rotated faster, using centrifugal force to evenly

cover the disc with lacquer. The excess coating is

collected as it spins off the disc and recycled. The

CD is then placed under a high intensity UV light

and the lacquer is cured in roughly 1.5 seconds. As

the CD leaves the press,it is optically scanned for

any imperfections.

How long does it take for all this? In the early days

of CDs, presses could turn out a CD every 10

seconds, today, that time has been cut to just over 3

seconds. If one single plant has 25 presses working

24 hours a day, based on a 3.5 second cycle time,

the plant could theoretically press 225 million discs

a year. Add the total number of plants around the

world, (hundreds at last count), and billions upon

billions of CDs are produced annually.

If treated carefully, a CD in this state should last

well beyond any of our lifetimes. Why only

should? For starters, there are some chemical

reactions that can occur with the lacquer used in the

1980ís. Many titles pressed during this time, when

placed next to a certain type of padding will self-

destruct. I am specifically referring to double CD

sets that would be packaged in the "Double-Fat

Jewel Boxes". A piece of padding was usually

placed on top of the CDs for protection. If left

touching each other for any long length of time, the

chemical interaction between the two would leave

the CD unplayable. The lacquer would break down

and let air oxidize the metal. The chemical structure

of the lacquer has since been changed. If you have

any of these double CD sets in your collection,

remove the padding immediately and hope for the

best.

Some of the items on display at the CAPS meeting.

|

|

The ways discs are treated often determine the

lifespan of the disc. Most of the general public

think the bottom of the disc is most susceptible to

damage. This is clearly not the case. The bottom of

the disc is easy to repair. If it gets dirty,it can be

cleaned with most any soft soap/dishwashing

detergent solution. If it gets scratched, it can

usually be buffed out. It takes heavy damage to the

underside of the disc to render it unplayable. A

scratch on the top of a CD,if deep enough, will cut

through the lacquer and destroy the metal and

connecting pit structure. This type of damage can

never be fixed. With this in mind, never stack your

CDs or keep them stored loosely on your desk. If

they are not in your player, they should be in a

protective jewel case. No exceptions.

Error correction comes into play if the CD player

canít read a defect on the disc. Unlike analog

records, which are linear, CDs use a non-linear

data encoding process. The digital information is

repeated, and scattered slightly in the code. If one

block of information is unreadable, the next block

to be read can be used to recover the lost data.

Here is a written analogy:

Analog

The Canadian Antique Phonograph Society holds

meetings at Centennial College, Progress Court,

Scarborough, Ontario. Meetings begin at

1pm. There is a 15-minute break between the

presentation and the member auction. Snacks are

served.

Mike holds the aluminum disc used to coat the

stamped CDs and a spindle which holds clear

CDs ready to coat.

|

|

Digital

The Canadian Antique Phonograph Society holds

meetings at Centennial College, College, The

Canadian Antique Phonograph Society holds

meetings at Centennial Centennial College, The

Canadian Antique Phonograph Society holds

meetings at

Place your finger across both paragraphs. Even

though your eyes cannot see every word, your brain

can put together the missing data in the digital

version. Your CD player uses a similar technique.

The last step in the manufacturing process is to

print the artwork on the face of the CD. Silk

screening is the most common type of printing

method. It can be a simple one-color text only print,

or it can be a 5-color photographic quality print.

Any color can be used. If an esoteric color is

needed,it is custom mixed on the spot using a

unique ink recipe (much like getting a special color

paint mix at your local paint store). Once again, a

UV system is used. The ink is applied one color at a

time, passing through a high intensity UV light to

dry the ink before the next color is applied. One

advantage to a full coverage print job is that it adds

another layer of protection to the CD. The UV ink

is extremely hard once cured, and if the ink canít

be scratched, neither can the surface beneath.

After printing, the CDs are assembled according to

the wishes of the client. In most cases the standard

jewel box is used. The entire process is automated.

Spindles of CDs are in one staging area, artwork in

another, jewel cases and trays in a third. On the

output side of the machine, the CDs are boxed and

prepped for shipping.

What will we be manufacturing ten, twenty, fifty

years from now? Only time will tell. Some predict

laser read holograms able to hold terabytes of

information will take over; others predict small

chips will hold the keys to the future. Whatever the

new delivery system might be, expect to hear from

the marketing departments. Iím sure the sign in the

window will read, "New Improved Double Plus

Good Perfect Sound Forever And Then Some.

|