|

Restoration of My Wurlitzer 500 Jukebox

by Mike Dicecco

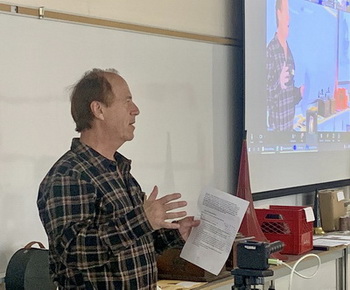

Mike Dicecco presenting his restoration project

at the

CAPS Show & Tell meeting, May 5, 2024

|

|

For my part of the presentation I chose to talk about the restoration of this vintage jukebox as itís such an unusual

piece; it took so long to fully restore and in the end it turned out so good (well beyond my initial expectations). I

had never performed a total restoration of this magnitude before, so it was both a labour of love and very much a

learning process. In hindsight, I really had no idea what I was getting myself into but itís fun from this perspective

to look back at the end results, and be proud!

Letís start by talking about what exactly is a "Wurlitzer 500"?

The late 1920ís and early 1930ís was a time of great electronic advancement in the playback of not only records,

but also "talkie" movies. Several manufacturers such as Capehart, RCA Victor, Seeburg, Rockola and AMI

(American Music Industries) began to design "commercial phonographs" (which later were called "jukeboxes" by

the public). One of the latecomers to this field was the Rudolph Wurlitzer Company, which in 1933 purchased the

Simplex changer mechanism and used it for years in all their products.

My Wurlitzer 500 as received (1995)

|

|

The early jukeboxes were essentially fashioned after the large home console radios/phonographs of the day, with sometimes a

viewing window at the top for the patrons to view the mechanism. Wurlitzer quickly led the field and discovered

that a jukebox would have more Ďplay appealí if it was brightly illuminated, as well as have a record changer that the customers could watch (therefore being more

profitable). They gradually started adding coloured

plastics, mirrors and later, bubble tubes, to make

their product stand out from the competition, and it

worked! Wurlitzer jukeboxes from this period command the highest prices today and are amazing show

pieces. Art Deco works of art. They are also a great

way to play some of your favourite 78 RPM records at

home.

For 1938 Wurlitzer offered three models: a 12-play

table-top machine, a smaller basic full-size model

600 (with no animation) and the largest top-of-the-line model being the 500. This played one side of 24

records, 10" 78 RPM. Itís a big beast, measuring 58"

high and 35" wide, with a weight of 410 lbs (without

records).

The Wurlitzer 500 model was the first jukebox to utilize animation. That is, in the front on either side of the

grille, were two rotating cages of translucent plastic

sheets that rotated around several light bulbs (driven

by tiny motors) and projected onto the front grille (or side pillars). The constant changing of colours created an incredible overall effect that must have been quite a novelty for those who first saw it in their favourite restaurant or

bar. Following this model, most full-size jukeboxes had some form of animation up until the early 1950ís, but this

was the first time this feature had been used.

Another unusual (for the time) aspect was separate bass and treble

controls on the amplifier, as a way to customize the sound coming

through the 15" field coil speaker.

Close up of the lower front.

Note the excessively damaged veneer and

the missing bottom trim which had to be

created by my friend Marty. The colour cylinders sheets were missing from beside the

grille, as they had rotted out. Replacement

sheets are available.

|

|

To complicate matters (from a restoration perspective) the model

500 was available in four different configurations: one with the animation unit in the pilasters (side pillars), one with the animation unit

shining on the grille (my unit). Therefore, some had red (or white)

pilasters and some had red (or white) grille plastics. There were also

two different coin units: one with mechanical coin counters (more

common) and another with an electric coin slot system that was

able to reject "slugs" (my unit) more accurately. This is important,

because even though a dealer may have some used parts for a

Wurlitzer 500, thereís a 50% chance that they will not be the right

ones!

To add to the scarcity of this machine, during World War II manufacturers were not allowed to make much civilian equipment (due to

metal shortages), and jukeboxes were deemed non-essential

(except perhaps for entertaining the troops). Wurlitzer came up with

a "Victory" model that would appear to put a new jukebox in front of

the public (and combat men), but it was actually just a way of encasing an older jukebox mechanism in a new cabinet. As such, many of

the pre-War machines had their cabinets scrapped and their innards

re-purposed in a Victory jukebox. The earlier and desirable machines

such as W600, W500, and W24 models were destroyed, reducing

the surviving numbers (and original parts).

I mention all of the above, because these factors conspired to make

it much more difficult to find original parts when I was searching them out for my restoration. It all

goes back to doing a full and proper

research before buying and beginning a vintage project.

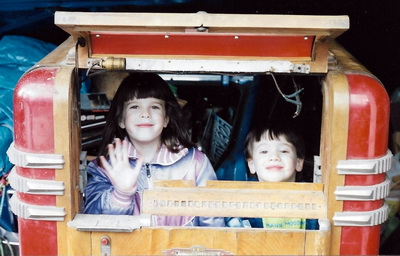

My kids Veronica (age 6) and Raymond (age 4) decided to help out by

climbing inside the cabinet. They are now in their 30ís and want nothing to

do with jukeboxes! Is this Wurlitzer the cause?

|

|

Acquiring an Unrestored Wurlitzer 500, or "What Did I Get Myself Into"?

I had a couple of friends who were

travelling with a van to the Chicago

Coin-Op show in April 1995. They

would usually restore jukeboxes and

radios, sell them at the show, and

then bring more items back to continue the restoration cycle (and

make some good money in the process). I told them to keep an eye out

for an old Wurlitzer 78 RPM jukebox

if one came up for a good price (at

this point in my life I already had two

other jukeboxes, one that played 78ís

and the other 45ís. Another 78

Wurlitzer would be great for my large record collection). Several days passed by. I didnít think anything would come

up, which was good, because I had not told my wife Liz about it, and wasnít sure how she would appreciate another

big item coming into our house.

Minutes before leaving work on a Friday afternoon, I received a call from

one of my friends. He was so excited: "Mike, Mike; we found you a great

jukebox! Itís only $400 USD". Most of itís there, just needs a few parts

and cabinet work. Itís a steal!" I called Liz immediately, told her what a

great find my friends had made, AND they would be kind enough to

bring it back in their truck from Chicago, to my home in Toronto. How

could I lose?

Iíve stripped everything out of the cabinet and have it on my front lawn. Iíve

saved time and money by doing this

part of the work myself, as well as

re-painting the inside of the cabinet.

Itís ready to go to Martyís house

in Hamilton.

|

|

Liz could sense my excitement and quickly agreed. A few weeks later, on

a rainy spring afternoon my friends arrived with their open back truck

and my Wurlitzer, partially covered by a tarp in the back. I was in for a

shock: my friend had taken the mechanism out (so that he could restore

it for me), but there was so much else missing or damaged: tone arm,

tubes in the amplifier, title board, all the coin mechanism, both back

doors, and many small pieces removed along the way by others raiding

it for parts. The worst part was clearly the cabinet. Besides probably being in the rain all the way back from Chicago, there were large sections

of veneer missing, as well as major parts of the bottom front trim. The

veneer that was still on the cabinet was lifted and distorted (and therefore unusable).

Once my friends left, I stuck my head in the back of this old relic and

thought "What have I gotten myself into? Itís such a wreck!" It was dirty

and dusty; neglected and picked over for parts. Could it ever be restored

to some degree, and actually work? My glimmer of hope came that night,

when I decided to plug in a couple of light bulbs that were still in the cabinet. The glowing red image somehow gave me hope that Iíd be able to do

something, somehow to get this former beauty working again. Most of the "Before" pictures accompanying this article were taken on the day of arrival. I wanted to capture the true condition before I went to work on it, which turned out to be the next three years.

On The Long Road to Restoration

My first step was to wash down as best I could the interior of the

cabinet. In old jukeboxes there is usually much more than dirt to

clean out. There is the dreaded nicotine from years of patrons

smoking around the jukebox. Apparently, itís still cancerous, so if

you do ever get an unrestored juke, be sure to wear heavy rubber

gloves when you are removing the dirt and grime. Wearing a mask

too is probably a good idea.

My friend Marty has re-veneered the cabinet

and created the missing front lower trim. Itís

now ready to be sanded, stained and lacquered. It also had to be re-glued and

clamped to restore the original structure

which deteriorated due to moisture and

neglect.

|

|

Take lots of pictures of how everything goes together, before you

start removing parts. For instance, I removed all the light bulb

sockets and cloth covered original wiring (each light piece would

later be re-soldered with the proper wiring, but itís hard to remember exactly how it all went together). At the time I did this machine,

we only had printed film photographs, itís so much easier

today with digital pictures.

There are manuals for this model, and others from the late

1930ís, but they are more for listing parts and making adjustments. The manuals do not often go into detail as to how all the

parts go together. You

may be lucky enough

to find someone online

who has a similar machine and will send

you pictures, but the

easiest way is to just

document it fully yourself before you begin to disassemble. I also found it helpful to put the

various small screws and pieces in clear bags and carefully label each

one.

My goal was to strip the cabinet down to the bare essentials, repaint

the inside with the correct colours, and then have the outside veneer

done by someone with the proper skills (as I knew it was beyond by

ability). To restore something as big and complicated as a vintage jukebox, itís very similar to doing an old car. You divide it up into various

sub structures (that require special skills) and address each area separately: wood cabinet restoration, rebuilding the amplifier, volume control and speaker, re-plating the metal, cleaning and rebuilding the

mechanism, electric motor rebuilding and other cosmetics. Fortunately,

I knew a few people who were able to help me with the work that I

could not do myself.

I should point out that restoring jukeboxes is different from other antiques in that it is perfectly acceptable to refinish, re-paint, re-plate, and

replace some of the original parts if needed. The goal is to make it look

as close as possible to when it first came out of the factory. The same

logic is used in restoring an antique car or truck. Fortunately, many reproduction parts are available to help. It would of course be preferable to

obtain a jukebox in mint condition, but those are few and far between.

Most have served a very hard life and then ended up neglected in damp storage for years.

Hereís a picture of a red pilaster plastic

after spraying Fantastic cleaner on it.

Note the bubbles have turned brown

and the sink has a gross tar-like residue. Thatís the remnants of cigarette

smoke which is common on old jukeboxes (as well as potentially cancer

causing!). Gloves and mask are

mandatory.

|

|

Clearly my biggest challenge would be to have the cabinet properly

restored. Fortunately, through my initial friends (who found this juke

for me) I met a very skilled craftsman named Marty MacKenzie of

Hamilton. Some of you may know him, as he was a CAPS member

for several years. Marty worked on my Wurlitzer cabinet over the

summer months of 1995. He disassembled the entire unit, then reglued it back together to ensure proper strength and fit.

Marty was able to recreate the missing base trim in the front (which

would have been impossible to find), and also used a veneer that

was as good as, or more ornate than the original (see photos). Several layers of hand rubbed lacquer created the glamorous shine.

The photos document the restoration as it progressed. One of the

best parts of restoring this machine has been the friendship that I

have to this day with my friend Marty.

The electronics (tube amplifier and volume control) were sent out to

an old-timer radio repair man who knew exactly what to do with

them. The parts manuals fortunately had the schematics for the amplifier, which made it much easier to rebuild. In case youíre not familiar with restoring vintage electronics, the capacitors are always

replaced, and resistors are

checked to ensure

that they are within

specifications. Surprisingly itís still

relatively easy to obtain these parts, as well as electronic tubes

(there are many dealers who sell them).

I was fortunate in that all of the original plastics were present. The

condition was a little rough, but with water-sandpaper and a lot of

buffing they shined up like new. The plastics in pre-war Wurlitzers

were about ľ" thick, and are often salvageable. Post war they

started using much thinner plastics that shrank with the heat of

the light bulbs, so they usually have to be replaced with reproductions (that are hopefully available). Points like this I learned as I

went along. However, it would have been better if I had researched this more before purchasing, as I could have run into

serious issues had my machine been missing any plastics.

The cabinet is back at my house, beautifully

re-finished. The mechanism has been

re-installed too. Itís getting there!

|

|

A word of caution: since jukeboxes were usually in public places

where people congregated, they were subject to years of tobacco

smoke. Every part of them is coated with nicotine that could be

potentially cancer causing. See my picture of what came off one

of the red plastic pieces. Gross! Be sure to wear gloves and a

mask when cleaning something like this.

The original tone arm was missing, as was the heavy magnetic

cartridge (that used a Perm-O-Point needle). Once I found a replacement tonearm, I elected to upgrade to a modern ceramic cartridge that gave improved sound, and most importantly tracked at a

much lighter weight (15 grams vs the original 120+ grams). Most people will make this upgrade on vintage jukeboxes to

help save their precious vintage 78ís. Visually the

change is hardly noticeable.

Electroplating this machine was more expensive due to

the large ornate grille, as well as numerous intricate

parts. The original plating was nickel, which was now a

dull gray and looked terrible. I chose to go with chrome

to give a brighter sheen

that lasts (and never

needs polishing). Fortunately, at the time I

worked in downtown Toronto, and there was a

"hole in the wall" plating

company that did excellent work at very reasonable prices. I believe they

were shut down by environmental watch dogs in

the late 1990ís, long after all my plating needs

were met.

Light bulbs were another

challenge that would later

arise. Even though the

majority of the bulbs used

were standard incandescent 15 watt bulbs, four

areas used unusual Lumiline Bulbs. These are

elongated tubes (similar

to fluorescent) that use

an incandescent filament.

Fortunately, I was able to

get some at the time of

my restoration for about

$20 USD. (Currently there

is an LED replacement on

Amazon for "only" $130

per bulb!). This would add

a very large expense if

the restoration was done

today.

The elusive coin equipment that took me 17

years to locate and cost more than the original amount of the entire jukebox. This was

extremely difficult to find.

|

|

One part that took me

much longer than anticipated was re-wiring the entire cabinet, not only the lights,

but all of the components and a junction box. The original wiring had become old and brittle, truly a fire hazard. The problem is that Wurlitzer didnít use ordinary

lamp cord in their product. Instead they used a gold

cloth covered type wire (similar to that used on appliances of the time such as irons). This, too, increased

the restoration costs and involved more trimming and

soldering time (literally hundreds). To do a proper job

Iíd have to go with the original type of wiring. Fortunately, one of the suppliers was able to provide all I needed

(and it looks great).

As I reflect back on the restoration process, I recall that

one of the biggest obstacles was finding parts, as this

was before the internet was widely available. There

were two main suppliers at the time, both in Iowa: Victory Glass Jukebox (still going strong) and Jukebox

Junction (now defunct).

Between the two I was

able to obtain most of the

missing parts, and/or the

raw materials to fabricate

my own. Sometimes if

they did not have a part,

they were able to refer

me to other used parts

suppliers who might have

what I needed.

While Iím on the subject

of finding parts, I wanted

to mention the problem I

had in locating the missing coin mechanism for

this jukebox. I was told

after purchasing, that it

was common practise

when jukebox operators

retired their machines

from routes, to remove

the coin equipment so

that competitors could

not buy the used jukes

and muscle in on their

territories. As such, the

majority are missing

these important pieces

and when the parts become available, they command a very high price. It

took me 17 years to locate what I needed (off

eBay), and I paid more for

them than I did for the

entire jukebox! But for me

it was well worth it, as it

finally completed the entire machine. Again, this is

something I should have researched in detail before

purchasing, so that I would know what Iíd be up

against for a proper restoration, as well as the final

costs.

Tips For Restoration

Needless to say, restoring this jukebox was definitely a

learning process over a lengthy period of time. Iíd like to offer the following advice about restoring anything

similar:

Restored and ready to accept your money. Five cents per

play. It is such a sight to watch this beautiful 86-year-old

jukebox in action! Well worth the three years of effort to

complete it.

|

|

- Before you purchase any vintage piece, do some research. What is the unit worth fully restored? What

kind of demand is there for it? How many were manufactured? There is so much information (of varying

worth) on the internet. Itís all at your fingertips.

- Examine the condition of what youíre buying. Know

what is "good" about it, and what is missing or needs

extensive work. Because I bought this jukebox sight

unseen, I was relying on the enthusiasm of a friend

who thought he found a great deal for me. I should

have asked more specific questions. Today, we are

able to have a seller take several pictures and send

them in an instant. Itís always best to inspect in person

though so you can make a more informed decision.

Sellers always minimize what it will cost to fix and/or

restore something.

- In terms of doing research, try to find out what parts

are available to complete the restoration properly. Will

parts from a similar machine fit, or are they unique to the

one you want to buy? Are there suppliers who can sell

you the parts (both used and reproduction) for a reasonable price? Factor in exchange rates and duty too.

- Before you begin any disassembly or work, take lots

and lots of pictures. These will help so much when it

comes time to put it back together, and also stand as a

testament to your restoration skills.

- Break down the required work into several categories:

Is there cabinet refinishing involved? Can you do it

yourself, or will you have to farm it out? If the latter,

who would you use? Can you restore the mechanism

yourself, or would you give it to a professional (for vintage phonographs Iíd highly recommend any of the fellows who advertise in the APN if youíre planning on

restoring an old phonograph. You can also talk to fellow members. There is such a wealth of information in

CAPS!). Generally the less restoration you do yourself,

the more it will cost you for the overall project.

- If an original manual was once available, get a copy of

it. This will help immensely to explain adjustments,

parts, and mechanical functions (as well as help you

determine how much you can do yourself). Sometimes

you can find the manuals free, but pay for one if you

have to, as it will be invaluable and ultimately increase

the value should you later decide to sell.

- Donít underestimate your own abilities. Try doing some

repairs yourself and you may have more success than

you thought. Itís also very gratifying.

- Before you buy, ask yourself what the collectible will be

worth should you later want to sell it. Many times we

end up putting more time and money into something

than what it is ultimately worth in the market. If youíre

planning on keeping and enjoying it yourself for years,

then it doesnít really matter. However, if your goal is to

later flip it, the costs may make it prohibitive to purchase and restore.

"Before" (1995) and "After" pictures.

There are about three years between these photos, but the

transformation is indeed dramatic.

|

|

Conclusion

The accompanying "before" and "after" photographs

were taken with my film camera in 1995 and scanned

to digital later for the presentation at our CAPS meeting. They document the initial dilapidated condition

and the slow progression of restoration, which took

about three years (except for the coin mechanism,

which took 17 years!).

Was it worth it? For sure! It proudly sits in our living

room, and certainly commands attention and admiration from most visitors. Iíve had almost 30 years of

pleasure from it, and am still mesmerized by the amazing sound and beauty that it provides as it faithfully

plays some great 78s.

Would I do it all over again? Hmm, Iíd have to think

hard about answering that one! (but likely I would,

since Iíve learned so much by doing this one). I hope

you have enjoyed my description and documentation of

the restoration process for this vintage 1938 Wurlitzer

jukebox, and perhaps got a few pointers that may help

you, too.

|